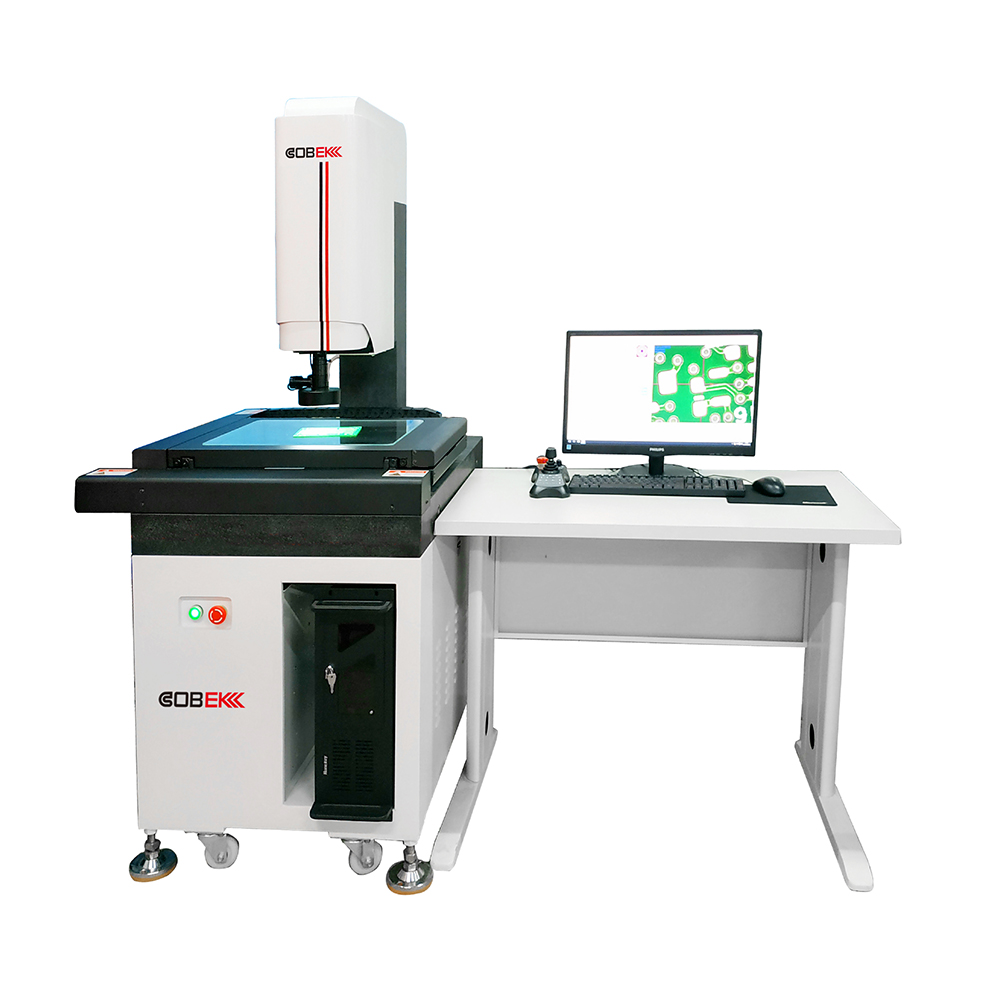

As one of the key equipment in industrial manufacturing, automatic standard image measuring instrument may cause serious interference to its service life and measurement accuracy if it is not reasonably applied in the process of use. In order to make the measuring instrument can be better used, I will give you a simple explanation of how to use it. 1, before lifting the product, the probe should be returned to the starting point, leaving more environment for the lifting part; When the product is lifted, it should be stable and not collide with all parts of the measuring instrument. 2. Assemble the parts reasonably, and ensure that the isothermal requirements of the parts and measuring instrument are met before assembly. 3, create reasonable coordinates to ensure that the built coordinates meet the needs of the design, in order to ensure that the tested data is correct. 4, when the programmed program starts, it is necessary to avoid collision between the probe and the product, so special attention should be paid to improving the turning point. 5. For some large and heavy molds and gauges, they should be taken down from the operating table immediately after measurement to prevent the automatic image measuring instrument from being in a load-bearing situation for a long time. The accuracy of the automatic standard image measuring instrument is the core of the precision testing instrument, if the accuracy can not be ensured, the equipment will lose its use value, the same as the quadratic measurement instrument, and the reasonable operation process is just to ensure the fundamental location of the quadratic image instrument.

查看分類